Electronic Rotary Filler

Conclusive benefits

- Electronic filling technology reaching unequalled levels of filling accuracy

- Common frame for optimal hygiene

- Technical design which adapts to different electronic filling technologies: weight or mass flow

- Optimal filling capacity for all 2 technologies, in terms of production speed efficiency and optimal use of space.

- Common chassis design with a number of possible structures, allowing for the inclusion of numerous environmental options

- Wide doors, allowing easy access to the filling and capping zone for easy maintenance or tool changeover

- Hema Quatro is equipped with a reduced-sized hopper and off-centered nozzles, ensuring minimal product loss between recipe changes.

Hema Quatro Care is dedicated to the particulated and non-particulated Home and Personal Care market. It benefits from Hema’s proven expertise built up over several years, in the area of filling complex products for large international groups.

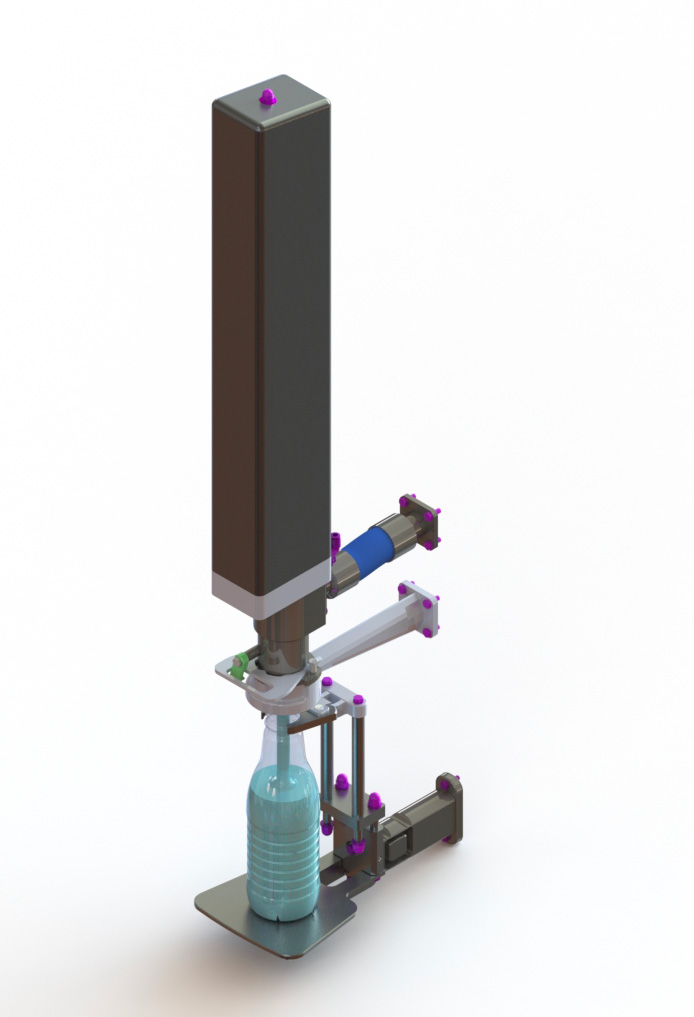

Quatro Care is available in Monobloc configuration with capper or Combi associating blowing, filling and capping for PET bottles.

Hema offers 2 filling technologies: WEIGHT – MASS FLOW

Filling Technologies

A simple principle: one weight, one measurement. Weight technology is the ideal solution for slightly viscous liquid products.

Special Features

Filling

Capping

Volume

Containers

Speed

Main Benefits

By means of individually controlling the net weight of a product, every bottle that enters and exits the filling machine is checked. The micro-processor in the electronic load cell pilots the filling according to the weight of the bottle.

The filling machine is equipped with a new DVS series weight detector, provided by our partner, Scaime. It is made of 100 % stainless steel and is the only electronically integrated EHEDG-certified detector. Its sturdy design meets several norm requirements, including IP69K.

Unrivalled filling accuracy

The highly precise piloting of the filling regulator (2 different speeds: high and low) obtains optimal filling accuracy, according to the format of the bottle, the bottle-neck space, the temperature and type of oil. Hema guarantees a standard deviation of less than 0.5 grams for 1 litre.

Filling flexibility

Thanks to its patented double flap valve, Quatro Care makes it possible to fill volumes from 80 ml to 5 litres at optimal speeds and without changing nozzles.

Environment and accessibility

The filler frame is in stainless steel and slopped to make it easy to clean (no adhesive areas).

Its wide doors allow easy access to the entire machine. An angular collecting trough recuperates the product at the end of production. Cleaning of the product circuit is done in a closed circuit.

Capping Turret

The capping turret meets your hygiene requirements.

Quick tool changeovers

The different coloured tools specific to each bottle format are available on the filling and capping turrets. They make tool identification easy. Without the need for special tools, the rapid fixing and indexing systems make it easy for the operator to set up. This means that time taken for tool changeovers is optimised.

Productivity optimisation

Hema Quatro Care is equipped with a reduced-sized hopper and remote nozzles, ensuring minimal product loss between recipe changes.

Concept Combi for PET packaging

Associated with a blower, the Combi integrates blowing, filling and capping in a common frame, for optimal efficiency.

By combining 3 functions in a common frame, the Combi makes the most of technological innovation in terms of blowing. It is associated with the latest generation of high-performance Hema Quatro filling machines.

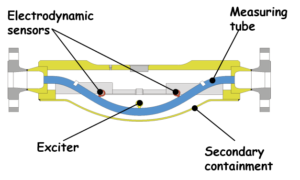

The principle: one speed, one measurement. This type of doser measures a mass which is dosed using a Coriolis sensor. Moreover, this type of sensor measures product density, temperature and speed.

A PLC system pilots the filling, according to the measurement taken by the mass-flow detector

Special Features

Filling

Capping

Volume

Containers

Speed

Main Benefits

The mass-flow filler is equipped with the latest checking technology and delivers clean product filling. The environment is hygienic, and the filling is precise, whilst keeping maintenance down to a minimum.

Unrivalled filling accuracy

Filling is extremely acurate, even at high speeds. Thanks to specially adapted nozzles, containers are filled up without drips or frothing. This filling technology guarantees a standard deviation of less than 0.5 grams for 1 litre.

Environment and accessibility

The filler frame is in stainless steel and slopped to make it easy to clean (no adhesive areas).

Its wide doors allow easy access to the entire machine. An angular collecting trough recuperates the product at the end of production. Cleaning of the product circuit is done in a closed circuit.

Capping Turret

The capping turret meets your hygiene requirements.

Productivity optimisation

Hema Quatro Care is equipped with a reduced-sized hopper and remote nozzles, ensuring minimal product loss between recipe changes.

Quick tool changeovers

The different coloured tools specific to each bottle format are available on the filling and capping turrets. They make tool identification easy. Without the need for special tools, the rapid fixing and indexing systems make it easy for the operator to set up. This means that time taken for tool changeovers is optimised.

Concept Combi for PET packaging

Associated with a blower, the Combi integrates blowing, filling and capping in a common frame, for optimal efficiency.

By combining 3 functions in a common frame, the Combi makes the most of technological innovation in terms of blowing. It is associated with the latest generation of high-performance Hema Quatro filling machines.

Mass flow Meter

Options & peripheral equipment

Cleaning and Sanitation in Place

Either an angular collecting trough or dummy bottles (weight technology only) are placed to recuperate the product at the end of the production line. The « dummy bottles » procedure enables a closed-circuit CIP to take place.

Control – Ejection

Any faulty, badly-filled or capped containers are ejected from the production line.

Smart cap dispensers and feeding systems

Various options are proposed:

Elevators that stock and transport the caps to the dispenser.

Elevator-Orientators select the direction and transport caps at high speed within the same machine. They replace the elevator-distributor duo.

Cap buffer is installed on the filling and capping monobloc in the Combi configuration. It receives the directed caps and feeds the cap turret with the caps.