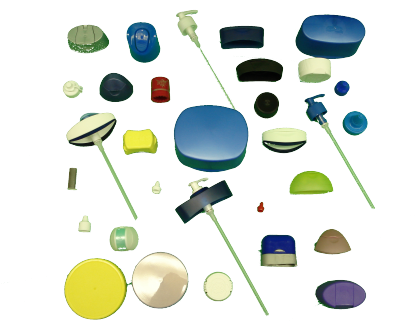

Cappers

Large variety of models

The various models can deal with different types and formats of caps (screw-on, snap-on, pump, trigger, etc.)

Innovative design

We offer 2 versions:

- Mechanical

- Brushless

The above use electronic control techniques for speed and coupling.

Each capping head is equipped with a servomotor which adjusts the capping specifications to the different types of cap.

Customised hygiene

A range of ultra-clean cappers is available to meet the requirements of a hygienic environment. Their design ensures optimal cleaning for the filling of sensitive products (dairy products, etc.).

Smart cap dispensers and feeding systems

Elevators that stock and transport the caps to the dispenser.

Elevator-Orientators select the direction and transport caps at high speed within the same machine. They replace the elevator-distributor duo.

Cap buffer is installed on the filling and capping monobloc in the Combi configuration. It receives the directed caps and feeds the cap turret with the caps.